Targeted deep purification treatment device

As a new type of flue gas treatment equipment newly developed by Hangtai, the targeted deep purification treatment device has the advantages of high efficiency, energy saving, and environmental protection, which can meet the market's demand for technological upgrades

Category:

Flue Gas Purification And Treatment Equipment

Product Description

As a new type of flue gas treatment equipment newly developed by Hangtai, the targeted deep purification treatment device has the advantages of high efficiency, energy saving, and environmental protection, which can meet the market's demand for technological upgrades

Performance Advantage

(1) Efficient denitrification performance: This system can achieve efficient denitrification by precise temperature control, allowing denitrification reactions to occur within an effective temperature window. The denitrification efficiency can usually reach over 85%, effectively reducing the emission concentration of nitrogen oxides in flue gas.

(2) Evaporative cooling has good temperature control effect: Evaporative cooling technology can quickly reduce the temperature of flue gas, which meets the requirements of dioxin control. At the same time, it can accurately lower the temperature of flue gas from high temperature to the temperature range suitable for denitrification reaction in a short time, creating good conditions for subsequent denitrification reaction, and also helping to reduce the generation of harmful substances such as dioxins.

(3) High system stability: Advanced automation control technology is adopted to monitor and adjust the operating parameters of the system in real time, such as temperature, pressure, flow rate, etc., ensuring stable operation of the system under different working conditions, reducing equipment failures and downtime, and improving equipment reliability and service life.

(4) Significant environmental benefits: In addition to effectively removing nitrogen oxides, controlling dioxins and other conventional pollutants, the system can also further remove VOCs, odors and other pollutants in the flue gas by adding washing towers, activated carbon adsorbers, etc., so that the flue gas can meet higher emission standards, reduce environmental pollution, and have good environmental benefits.

(5) Small footprint: The system's multi-path configuration can eliminate the independent emergency emission system in traditional exhaust system configurations, reducing the number of equipment, minimizing equipment footprint, and reducing chimney count. The system has a compact structure, reasonable layout, and relatively small footprint, making it suitable for installation and use in cremation sites with limited space and effectively saving site resources.

Product Parameters

| Serial No. | Project | Numerical Value |

| 1. | flue gas treatment capacity | 4680Nm³/h |

| 2. | System resistance | ~3500Pa |

| 3. | water consumption | 0.17~0.33m³/h |

| 4. | Urea consumption | 2.63(40%)kg/h |

| 5. | Installed power of purification system | 21Kw |

Product video

Contact Us

Address

No.1, Taishun Road, Lingang Economic and Technological Development Zone, Weihai, Shandong, China

What Makes HangTai So Different From Other Suppliers?

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

GET IN TOUCHRefined production

It has advanced modern production workshop to realize the fine manufacturing of intelligent cremation equipment.

Intelligent and environmentally friendly

To achieve short cremation time, high efficiency, energy saving and emission reduction, effective decomposition of harmful substances generated by the combustion process, and control of pollutant emissions from the source

Intelligent Control

One-button control, without human intervention, automatically complete the whole process of cremation of human remains

Modular Design

The whole equipment adopts modular design, compact structure, reasonable design, easy to transport and installation

24-Hour Service

When you have any questions at any time, we will respond and act quickly, serving you 24/7 at any time

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at 86-19963188989 or ht-business@ht-cremator.com, and we will respond to you within i hour.

Factory Environment

Standardization of production technology, refinement of manufacturing processes, intelligence of manufacturing processes, and modernization of enterprise management

Workshop1

The No.1 workshop is equipped with various types of CNC cutting machinery, CNC laser cutting equipment, CNC plasma cutting equipment, CNC machine tools, CNC machining centers, CNC shearing machines, CNC bending machines and related machine tools, as well as various crane lifting equipment. It is mainly used for storing raw materials and standard materials such as electrical appliances, as well as for raw material processing, cutting, and cutting projects.

Workshop2

The second workshop is equipped with CNC rolling machines, automatic welding of circumferential straight seams, oxygen welding equipment, carbon dioxide protection welding machines, electric welding machines, drilling machines, automatic painting and baking equipment, various types of crane lifting equipment, etc. Mainly carry out product welding manufacturing, equipment assembly and debugging, masonry, surface treatment of components, equipment assembly and other projects according to the design process requirements of the drawings.

Workshop3

Workshop 3 is equipped with CNC shearing machines, CNC slotting machines, CNC bending machines, oxygen welding equipment, welding machines, various types of crane lifting equipment, etc. Design the exterior of various products according to the drawings and complete the product exterior process. At the same time, Workshop 3 is a production workshop for Hangtai's ancillary products, producing fresh air disinfection equipment, relic incineration equipment, refrigeration equipment, and other funeral equipment.

Workshop4

There are equipment testing areas and finished and semi-finished product storage areas in Workshop 4. The equipment testing area of Workshop 4 has two sets of assembly and testing platforms, equipped with large unit lifting equipment, for technical acceptance, assembly, and debugging of finished products. After the equipment passes the furnace test, the products are stored in the warehouse.

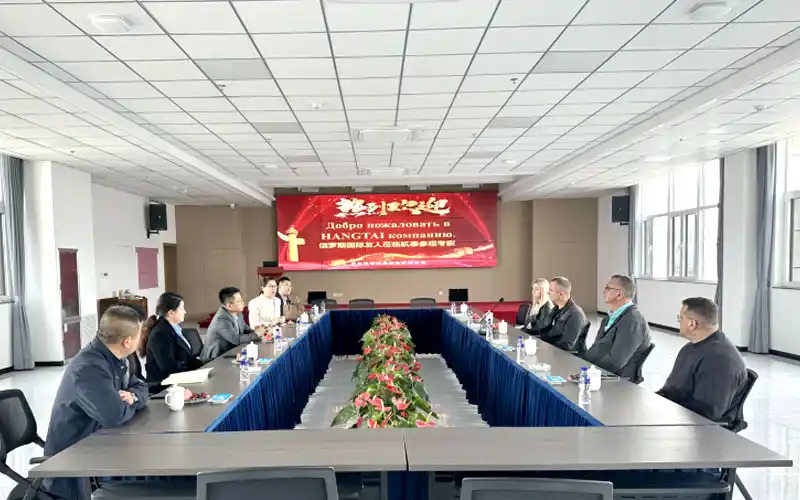

Customer visits

Welcome friends from all over the world to visit and explore

Argentine clients visiting

Argentine clients visiting

Argentine clients visiting

International Expo

International Expo

International Expo

German clients visiting

German clients visiting

German clients visiting

Russian clients visiting

Russian clients visiting

Russian clients visiting

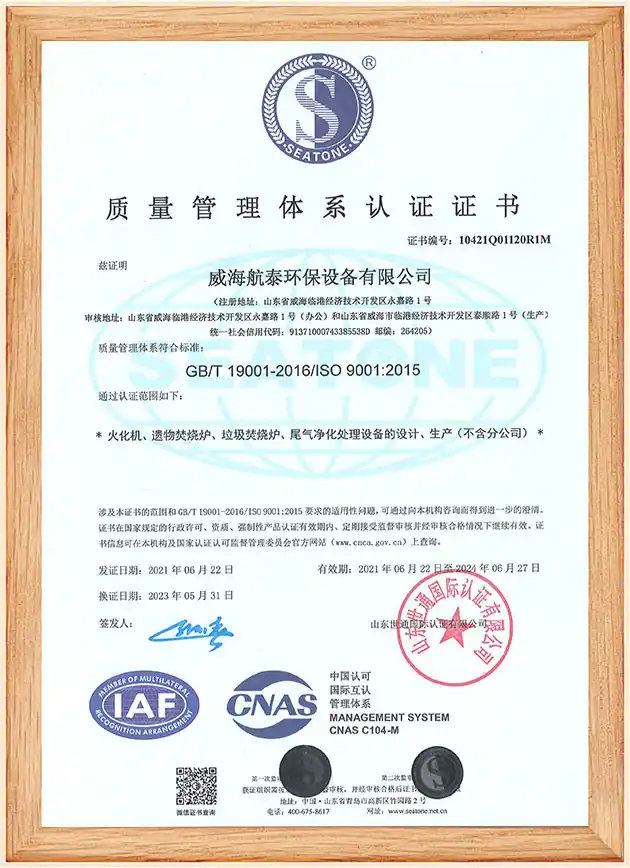

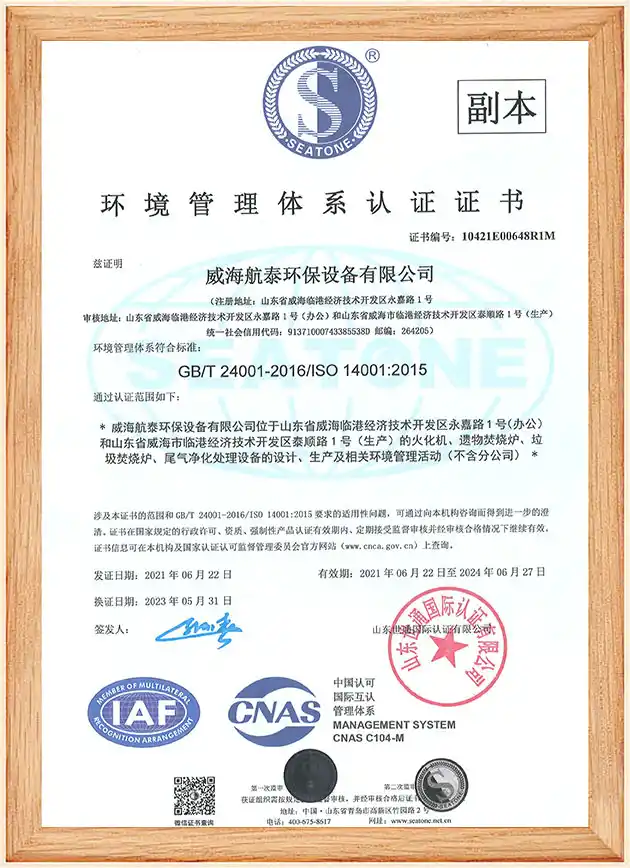

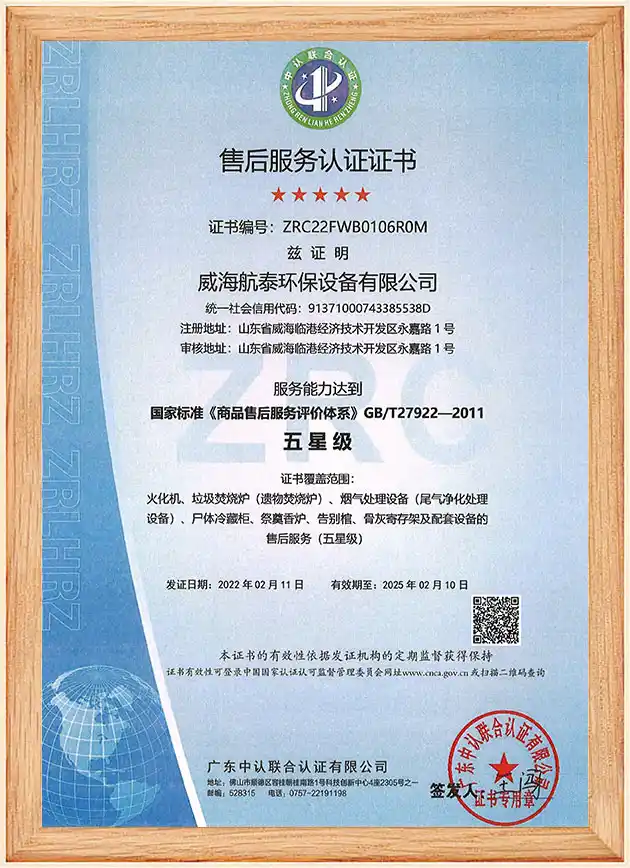

Quality Inspection

Excellent product quality and high brand reputation

Packaging for shipment

Years of cooperation with international logistics partners to ensure the safe arrival of your goods

Foreign cooperation

Win win cooperation and explore infinite possibilities.

FAQ

Excellent product quality and high brand reputation

Where is your factory?

What are your credentials?

Are you a factory or a trading company?

What is the minimum order quantity for the product and what is the production lead time after ordering?

Hot Products

Intelligent - Eco-friendly - Efficient - Energy-saving