Integrated flue gas purification and treatment equipment

Hangtai integrated flue gas purification and treatment equipment overcomes the shortcomings of traditional flue gas purification and treatment equipment

Keywords:

Category:

Flue Gas Purification And Treatment Equipment

Product Description

Hangtai integrated flue gas purification and treatment equipment overcomes the shortcomings of traditional flue gas purification and treatment equipment, such as limited installation sites and chaotic layout of the equipment, and the integrated design of the dust removal part of the equipment achieves the ideal flue gas purification effect.At the same time, the equipment realizes the whole quick installation, saves the installation time, and meets the standardized process from production to installation.

Product Parameters

| Serial No. | Name | Description Of Technical Indicators |

| 1. | Highly efficient cooling reactor | L×W×H=1650×880×3575mm(±5%) |

| 2. | Desulfurization and deacidification unit | L×W×H=630×590×1100mm(±5%) |

| 3. | Activated carbon adsorption device | L×W×H=630×590×1100mm(±5%) |

| 4. | Interceptor primary filter | L×W×H=1050×2155×3100mm(±5%) |

| 5. | Bag filter | L×W×H=3040×2155×3100mm(±5%) |

| 6. | Power of induced draft fan | 18.5KW |

| 7. | Number of filter bags | 168 articles |

| 8. | Filter bag specifications |

Φ130*1520mm |

| 9. | Filtration speed | 0.8-1.2m/s |

| 10. | Dust removal efficiency | 99.99% |

| 11. | Control method | The exhaust gas treatment system is equipped with two sets of control methods, manual and automatic. It can be operated in an integrated manner with the cremator. |

The Integrated flue gas purification and treatment equipment is a highly advanced and essential solution for addressing the complex challenges of flue gas emissions. This remarkable piece of equipment is designed to handle and treat a wide range of pollutants present in industrial flue gases.

Equipped with a series of cutting-edge technologies and components, it offers a comprehensive and efficient approach to flue gas purification. The system incorporates state-of-the-art filtration mechanisms that can effectively capture particulate matter, dust, and other solid pollutants. These filters are precisely engineered to ensure high removal efficiency and long-term durability.

The design of the Integrated flue gas purification and treatment equipment takes into account the specific requirements of different industries and applications. It can be customized and configured to meet the unique needs of each facility, ensuring optimal performance and compliance with environmental regulations.

The Integrated flue gas purification and treatment equipment also incorporates intelligent control and monitoring systems. These systems continuously monitor the flue gas composition, treatment efficiency, and operating parameters. They provide real-time feedback and alerts, allowing for timely adjustments and maintenance to ensure consistent and reliable performance.

Furthermore, the Integrated flue gas purification and treatment equipment is engineered for energy efficiency. It is designed to minimize energy consumption while maximizing the treatment effectiveness. This not only helps reduce operating costs but also contributes to a more sustainable and eco-friendly industrial process.

In conclusion, the Integrated flue gas purification and treatment equipment is a crucial tool in the fight against industrial pollution. It offers a reliable and effective means of reducing harmful emissions, protecting the environment and human health. With its advanced features, customizable design, and energy-efficient operation, it is set to play a vital role in the drive towards a cleaner and more sustainable future for industries worldwide.

Product video

Contact Us

Address

No.1, Taishun Road, Lingang Economic and Technological Development Zone, Weihai, Shandong, China

What Makes HangTai So Different From Other Suppliers?

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

GET IN TOUCHRefined production

It has advanced modern production workshop to realize the fine manufacturing of intelligent cremation equipment.

Intelligent and environmentally friendly

To achieve short cremation time, high efficiency, energy saving and emission reduction, effective decomposition of harmful substances generated by the combustion process, and control of pollutant emissions from the source

Intelligent Control

One-button control, without human intervention, automatically complete the whole process of cremation of human remains

Modular Design

The whole equipment adopts modular design, compact structure, reasonable design, easy to transport and installation

24-Hour Service

When you have any questions at any time, we will respond and act quickly, serving you 24/7 at any time

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at 86-19963188989 or ht-business@ht-cremator.com, and we will respond to you within i hour.

Factory Environment

Standardization of production technology, refinement of manufacturing processes, intelligence of manufacturing processes, and modernization of enterprise management

Workshop1

The No.1 workshop is equipped with various types of CNC cutting machinery, CNC laser cutting equipment, CNC plasma cutting equipment, CNC machine tools, CNC machining centers, CNC shearing machines, CNC bending machines and related machine tools, as well as various crane lifting equipment. It is mainly used for storing raw materials and standard materials such as electrical appliances, as well as for raw material processing, cutting, and cutting projects.

Workshop2

The second workshop is equipped with CNC rolling machines, automatic welding of circumferential straight seams, oxygen welding equipment, carbon dioxide protection welding machines, electric welding machines, drilling machines, automatic painting and baking equipment, various types of crane lifting equipment, etc. Mainly carry out product welding manufacturing, equipment assembly and debugging, masonry, surface treatment of components, equipment assembly and other projects according to the design process requirements of the drawings.

Workshop3

Workshop 3 is equipped with CNC shearing machines, CNC slotting machines, CNC bending machines, oxygen welding equipment, welding machines, various types of crane lifting equipment, etc. Design the exterior of various products according to the drawings and complete the product exterior process. At the same time, Workshop 3 is a production workshop for Hangtai's ancillary products, producing fresh air disinfection equipment, relic incineration equipment, refrigeration equipment, and other funeral equipment.

Workshop4

There are equipment testing areas and finished and semi-finished product storage areas in Workshop 4. The equipment testing area of Workshop 4 has two sets of assembly and testing platforms, equipped with large unit lifting equipment, for technical acceptance, assembly, and debugging of finished products. After the equipment passes the furnace test, the products are stored in the warehouse.

Customer visits

Welcome friends from all over the world to visit and explore

Argentine clients visiting

Argentine clients visiting

Argentine clients visiting

International Expo

International Expo

International Expo

German clients visiting

German clients visiting

German clients visiting

Russian clients visiting

Russian clients visiting

Russian clients visiting

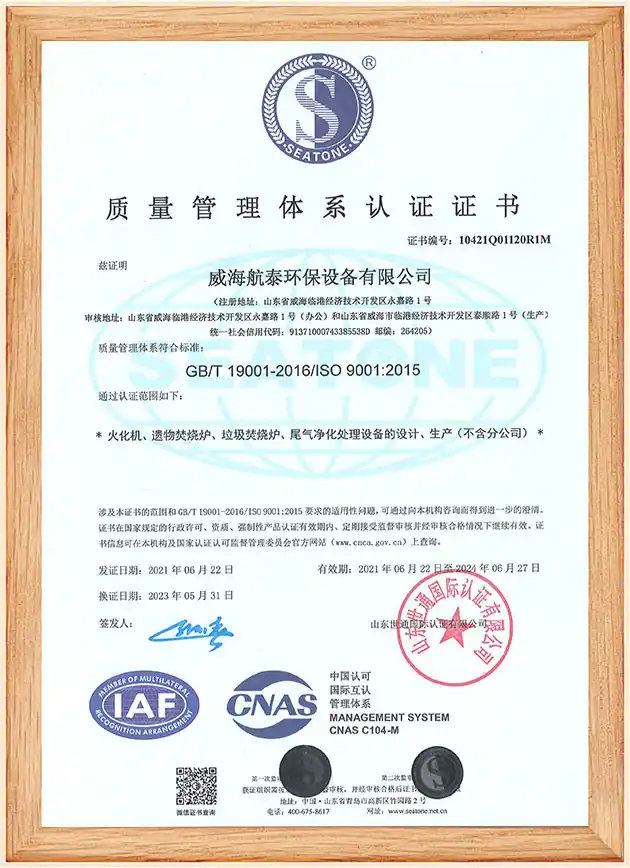

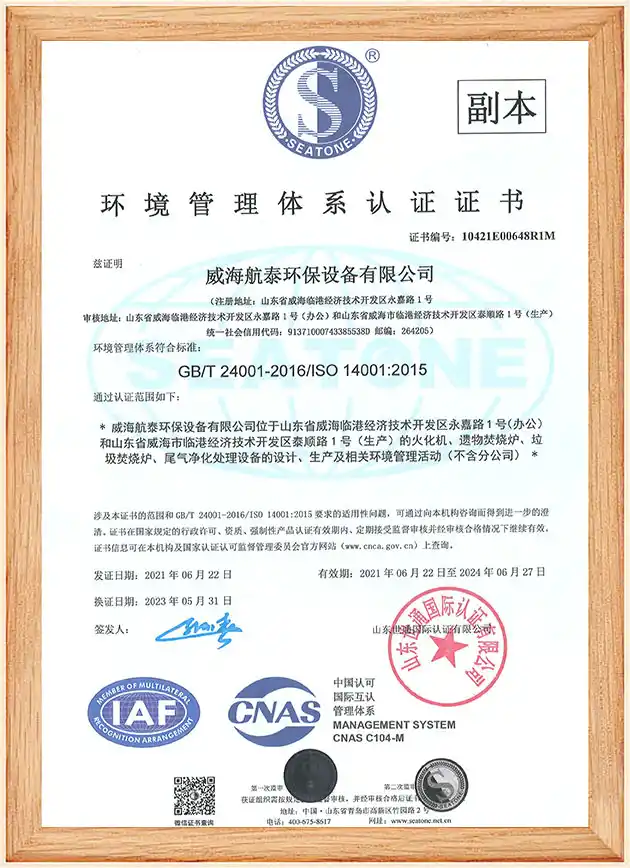

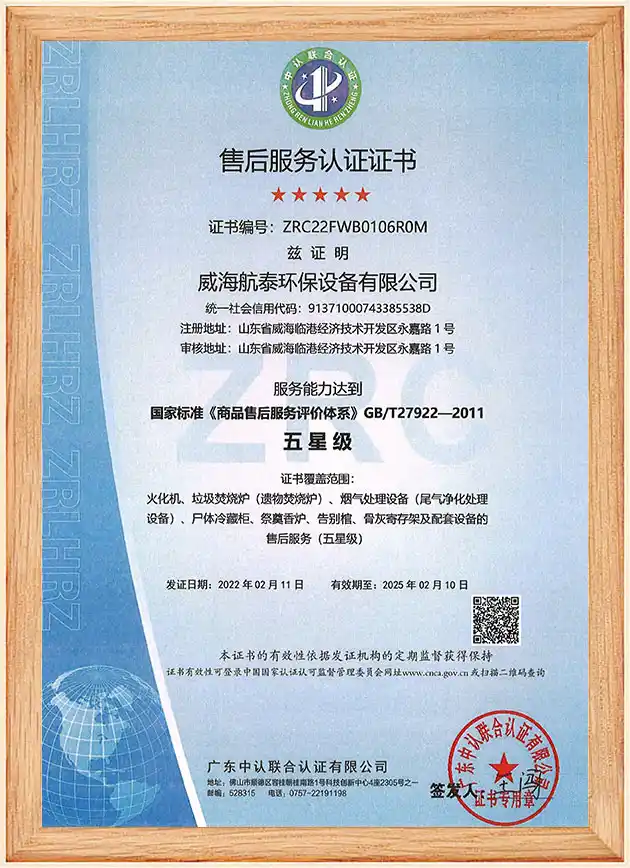

Quality Inspection

Excellent product quality and high brand reputation

Packaging for shipment

Years of cooperation with international logistics partners to ensure the safe arrival of your goods

Foreign cooperation

Win win cooperation and explore infinite possibilities.

FAQ

Excellent product quality and high brand reputation

Where is your factory?

What are your credentials?

Are you a factory or a trading company?

What is the minimum order quantity for the product and what is the production lead time after ordering?

Hot Products

Intelligent - Eco-friendly - Efficient - Energy-saving