Intelligent Cremation Machine

HT-2020-D

Single bed ash picking cremator/Double bed ash picking cremator/Flatbed cremator Natural Gas/Diesel.

Keywords:

Category:

Intelligent Cremation Equipment

Product Description

Built-in various sensing devices

Remote control, remote diagnosis, remote maintenance and upgrading.

Intelligent temperature and pressure control

Adaptive speed interpolation smoothing technology is adopted in the body feeding system, smooth and noiseless.

Integral quick-assembly / on-site masonry

Product Parameters

| Technical Parameters | |

| Equipment Model | HT-2020(D) |

| Furnace Size | LxWxH=3600x2400x3290(mm) |

| Furnace Chamber Size | LxWxH=2240x700x650(mm) |

| Continuous Average Cremation Time | ≤45 minutes/unit (more than 3 consecutive cremations, non-frozen remains) |

|

Gas Consumption |

≤40 cubic metres/unit (more than 3 consecutive cremations, non-frozen remains) |

| Fuel consumption | ≤35 litres/unit (more than 3 consecutive cremations, non-frozen remains) |

| Environmental Conditions For Normal Use | -20℃-+40℃, below 5000 meters above sea level |

| Continuous Operating Temperature Of Main Combustion Chamber | ≥850℃ |

| Secondary Combustion Chamber Operating Temperature | ≥850℃ |

| Furnace Working Pressure | -5--30Pa |

| System Operating Voltage | AC380V,50--60Hz |

| Blower, Induced Draft Fan Noise | ≤80 dB |

| Smoke Exhaust Method | Downward smoke evacuation |

| Control Method | Intelligent control of combustion technology, initially without human intervention |

| Emission Standard | Equipped with tail gas purification and treatment equipment, the emission is far better than GB13801-2015 Chinese standard and related standard requirements. |

The Intelligent Cremation Machine represents a significant advancement in the field of funeral services. This remarkable device is designed to handle the cremation process with utmost efficiency and sensitivity.

The intelligent aspect of the Intelligent Cremation Machine lies in its ability to adapt and optimize based on different scenarios. It can analyze various factors such as the size and weight of the body to determine the ideal cremation settings. This ensures that each cremation is carried out precisely and effectively.

The Intelligent Cremation Machine is also equipped with advanced filtration systems to minimize the release of harmful substances into the environment. This shows a commitment to environmental protection and compliance with strict regulations.

With its remote monitoring and control capabilities, operators can manage and oversee the cremation process from a distance, providing added convenience and flexibility. Additionally, detailed reports and data analytics can be generated, offering valuable insights for improved service delivery.

The aftercare of the ashes is also carefully considered. The Intelligent Cremation Machine ensures that the ashes are collected and presented in a respectful manner.

In summary, the Intelligent Cremation Machine is a cutting-edge solution that combines technological innovation with human compassion. It provides a reliable and efficient means of conducting cremations while maintaining the highest standards of quality and respect. It truly is a remarkable product that is transforming the way we approach the final journey of our loved ones.

Product video

Intelligent Cremation Machine

Contact Us

Address

No.1, Taishun Road, Lingang Economic and Technological Development Zone, Weihai, Shandong, China

What Makes HangTai So Different From Other Suppliers?

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry

GET IN TOUCHRefined production

It has advanced modern production workshop to realize the fine manufacturing of intelligent cremation equipment.

Intelligent and environmentally friendly

To achieve short cremation time, high efficiency, energy saving and emission reduction, effective decomposition of harmful substances generated by the combustion process, and control of pollutant emissions from the source

Intelligent Control

One-button control, without human intervention, automatically complete the whole process of cremation of human remains

Modular Design

The whole equipment adopts modular design, compact structure, reasonable design, easy to transport and installation

24-Hour Service

When you have any questions at any time, we will respond and act quickly, serving you 24/7 at any time

Need Assistance? We're Here To Help!

To request a quotation or locate your local distributor, please fill out the form below.lf you cannot find the product you need.

feel free to contact us at 86-19963188989 or ht-business@ht-cremator.com, and we will respond to you within i hour.

Factory Environment

Standardization of production technology, refinement of manufacturing processes, intelligence of manufacturing processes, and modernization of enterprise management

Workshop1

The No.1 workshop is equipped with various types of CNC cutting machinery, CNC laser cutting equipment, CNC plasma cutting equipment, CNC machine tools, CNC machining centers, CNC shearing machines, CNC bending machines and related machine tools, as well as various crane lifting equipment. It is mainly used for storing raw materials and standard materials such as electrical appliances, as well as for raw material processing, cutting, and cutting projects.

Workshop2

The second workshop is equipped with CNC rolling machines, automatic welding of circumferential straight seams, oxygen welding equipment, carbon dioxide protection welding machines, electric welding machines, drilling machines, automatic painting and baking equipment, various types of crane lifting equipment, etc. Mainly carry out product welding manufacturing, equipment assembly and debugging, masonry, surface treatment of components, equipment assembly and other projects according to the design process requirements of the drawings.

Workshop3

Workshop 3 is equipped with CNC shearing machines, CNC slotting machines, CNC bending machines, oxygen welding equipment, welding machines, various types of crane lifting equipment, etc. Design the exterior of various products according to the drawings and complete the product exterior process. At the same time, Workshop 3 is a production workshop for Hangtai's ancillary products, producing fresh air disinfection equipment, relic incineration equipment, refrigeration equipment, and other funeral equipment.

Workshop4

There are equipment testing areas and finished and semi-finished product storage areas in Workshop 4. The equipment testing area of Workshop 4 has two sets of assembly and testing platforms, equipped with large unit lifting equipment, for technical acceptance, assembly, and debugging of finished products. After the equipment passes the furnace test, the products are stored in the warehouse.

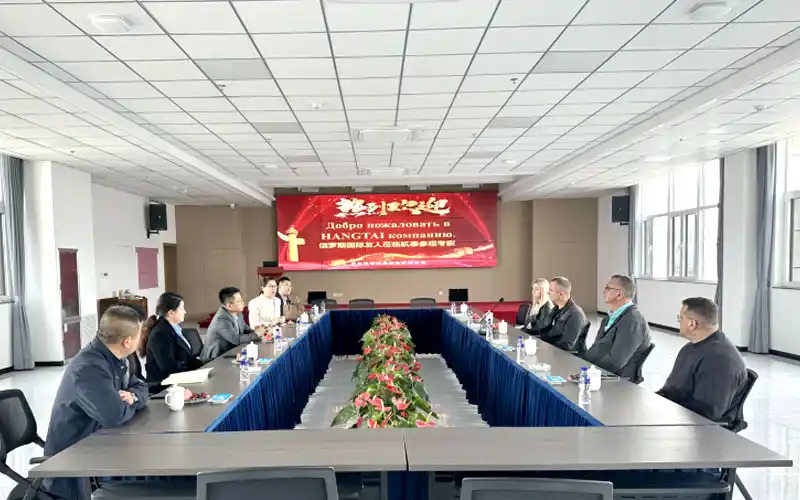

Customer visits

Welcome friends from all over the world to visit and explore

Argentine clients visiting

Argentine clients visiting

Argentine clients visiting

International Expo

International Expo

International Expo

German clients visiting

German clients visiting

German clients visiting

Russian clients visiting

Russian clients visiting

Russian clients visiting

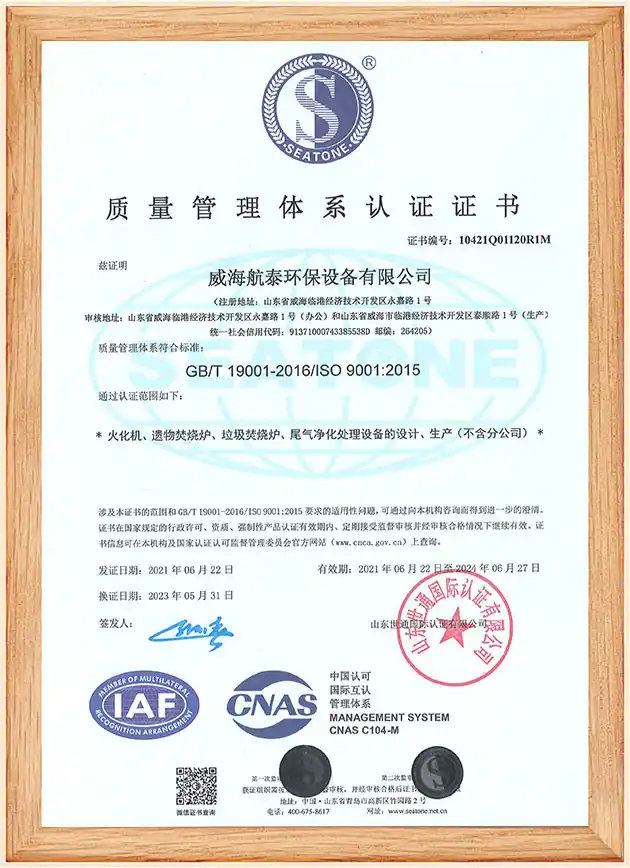

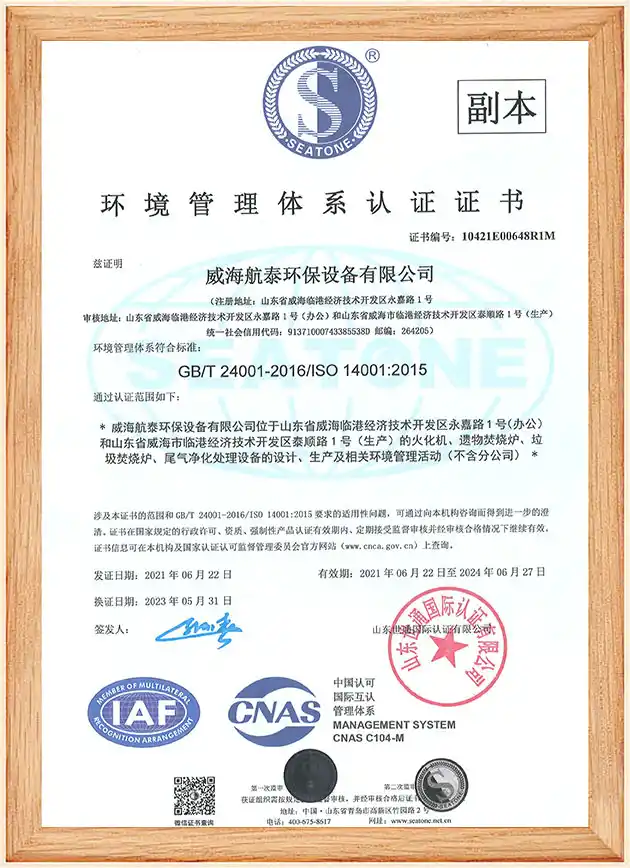

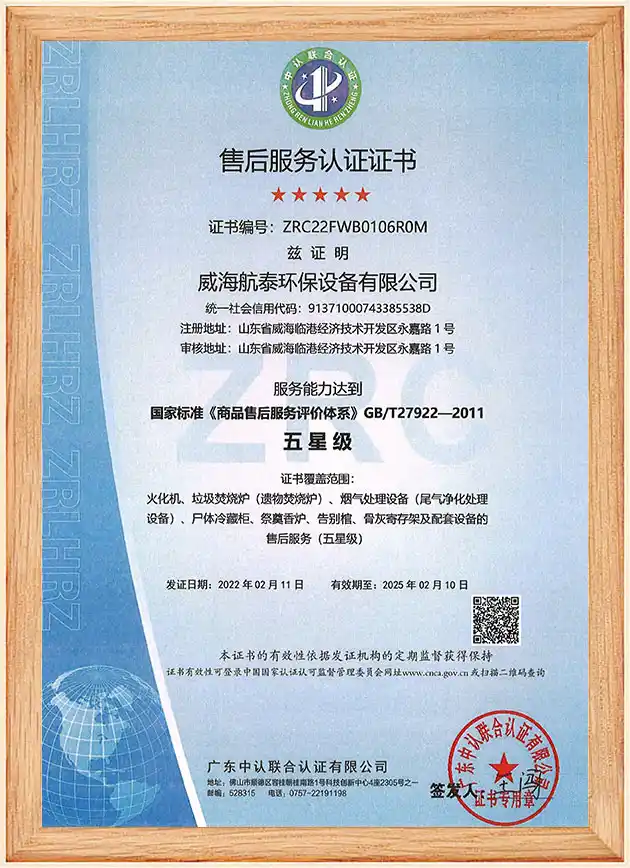

Quality Inspection

Excellent product quality and high brand reputation

Packaging for shipment

Years of cooperation with international logistics partners to ensure the safe arrival of your goods

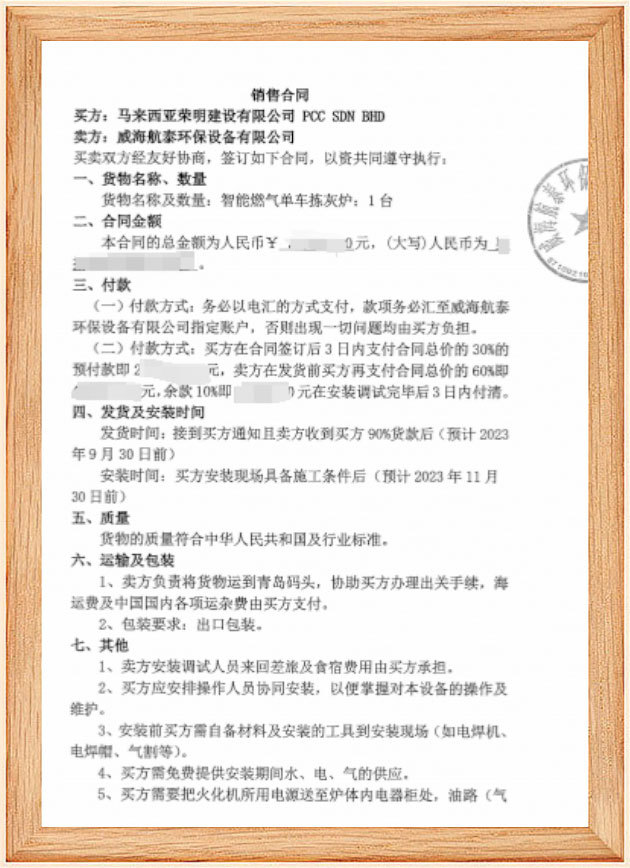

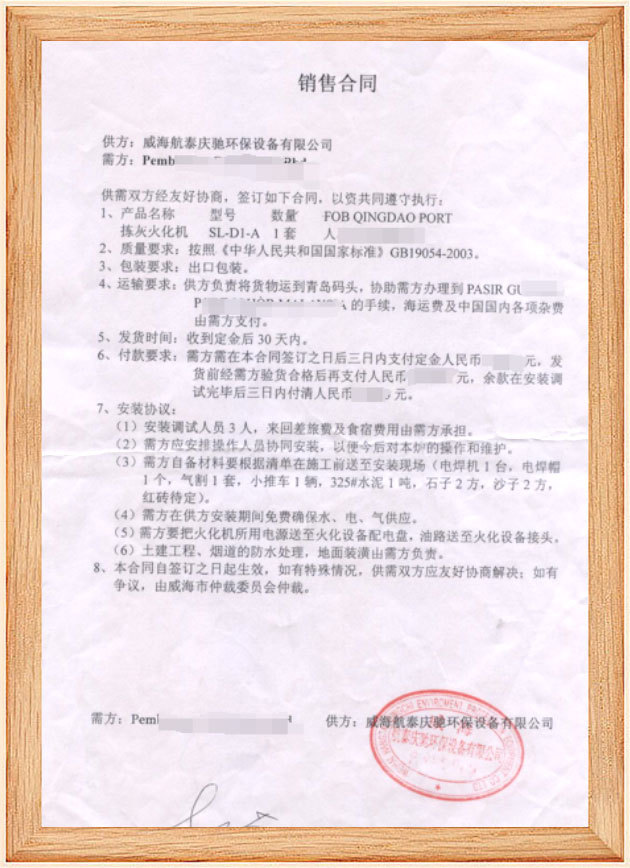

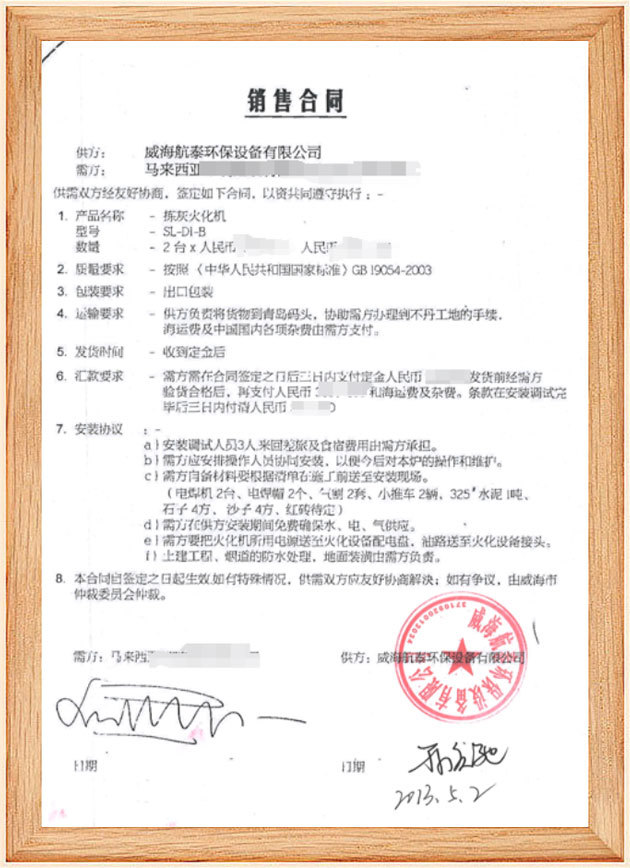

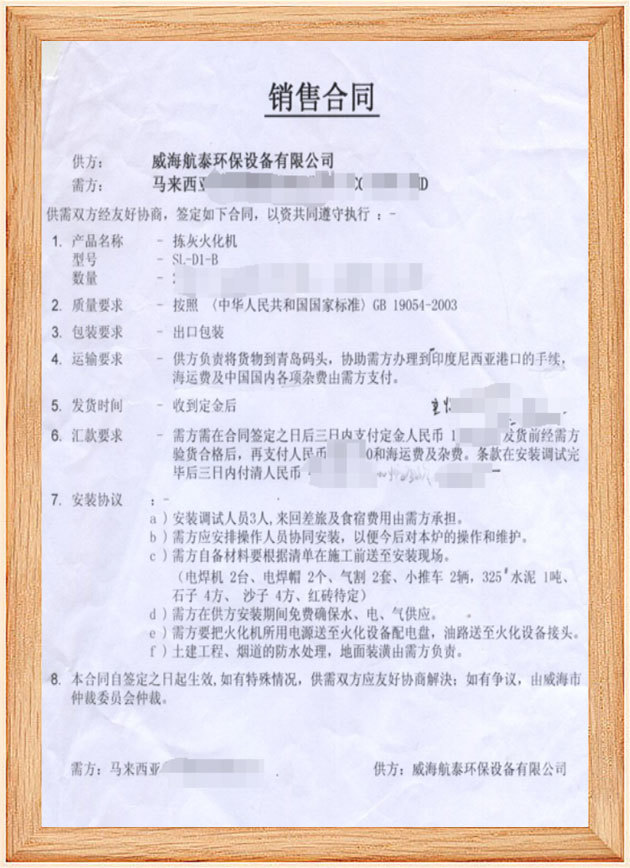

Foreign cooperation

Win win cooperation and explore infinite possibilities.

FAQ

Excellent product quality and high brand reputation

Where is your factory?

What are your credentials?

Are you a factory or a trading company?

What is the minimum order quantity for the product and what is the production lead time after ordering?

Hot Products

Intelligent - Eco-friendly - Efficient - Energy-saving